Uneven brightness, visible hot spots, and poor diffusion are common problems in backlit onyx projects. LED Sheet Light solves these issues with uniform, high-density illumination. Read on for the complete guide.

Backlit onyx lighting uses high-density LED Sheet Light positioned behind translucent onyx panels to reveal natural veining and color variations. To achieve a perfect effect, the light source must deliver uniform brightness, zero visible hot spots, appropriate installation depth (20–80 mm), and a suitable color temperature (3000K–4000K). LED Sheet Light is the most reliable solution because it covers the entire surface evenly, fits tight spaces, and provides consistent illumination across large panels.

Backlighting onyx is visually stunning but technically challenging. Onyx varies in thickness and translucency, so achieving uniform lighting requires the correct light source, brightness level, and installation conditions. The sections below explain the science, engineering requirements, and best practices to achieve professional results.

What Makes Onyx Suitable for Backlighting?

Onyx is naturally semi-transparent, allowing light to pass through its layered mineral structure. Backlighting highlights veining, depth, and color gradients, turning the stone into a glowing decorative feature. However, because onyx is not uniformly translucent, achieving even light requires a high-density source like LED Sheet Light.

Onyx is composed of layered calcite and aragonite minerals, which scatter light irregularly.

This makes the stone highly responsive to backlighting—veins appear deeper, colors intensify, and the entire surface gains a dramatic luminous effect.

But this same property also causes challenges: certain regions may absorb more light, while thinner sections glow more intensely.

Therefore, the backlighting system must compensate for these variations using:

Dense LED array layout

Stable brightness across the entire plane

Controlled installation depth

Consistent color temperature

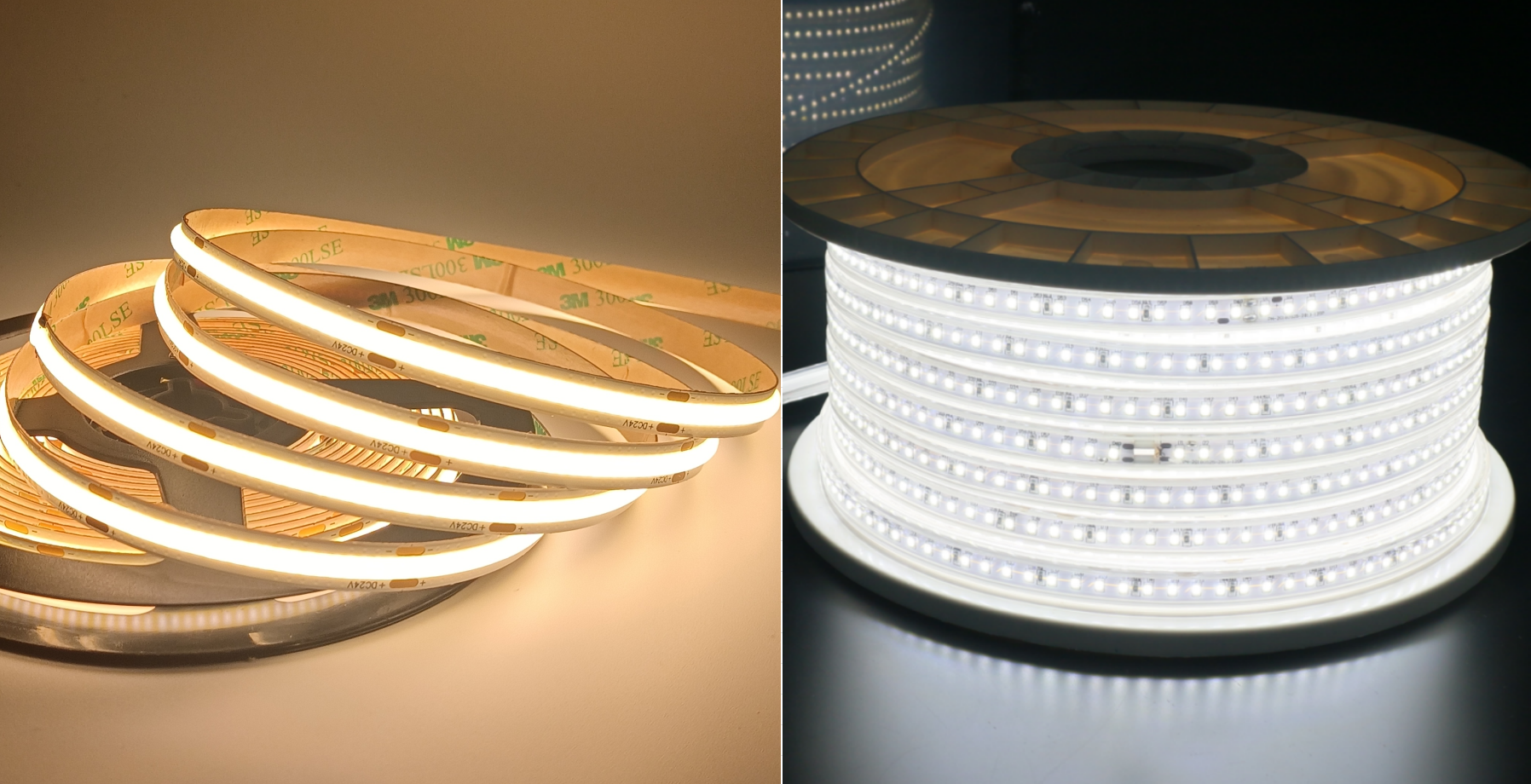

LED strips cannot handle these optical challenges because their linear spacing creates shadows and bright lines.

LED Sheet Light, by contrast, distributes light uniformly across the entire surface.

Why Do Many Backlit Onyx Installations Fail?

Most failures are caused by insufficient diffusion, low LED density, visible hot spots, uneven installation depth, or incorrect selection of color temperature and brightness.

Common reasons include:

1. LED dots visible through the stone

Standard LED strip spacing (16–28 mm) is too wide, causing “striping” on the stone surface.

2. Uneven illumination

Onyx is rarely uniform in thickness, so inconsistent lighting quickly becomes obvious.

3. Not enough installation depth

LED strips usually require 60–100 mm of space to diffuse properly.

4. Brightness insufficient for thick stone

Dense or darker onyx slabs can absorb up to 50% of light output.

5. Poor heat management

Improper installation causes brightness drop over time.

Therefore, the most effective solution is a surface-lighting source instead of a linear-lighting source.

Why Is LED Sheet Light the Best Solution for Backlit Onyx?

LED Sheet Light provides uniform, dotless, high-density illumination with minimal installation depth. Its full-surface LED matrix eliminates striping and delivers consistent brightness across the entire stone panel.

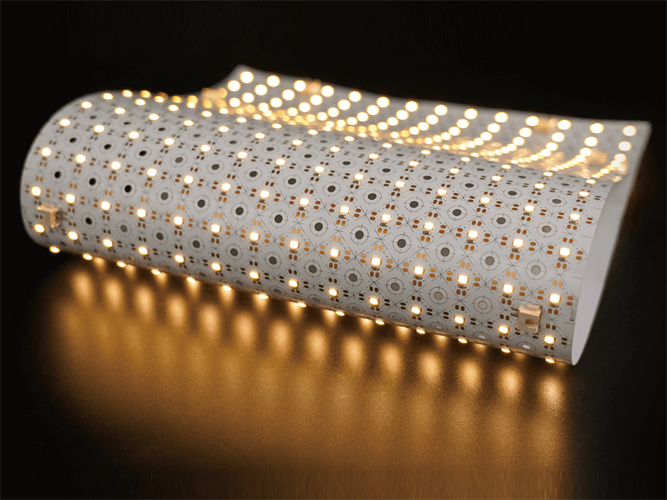

LED sheet modules (392 / 784 / RGBW) are engineered for surface illumination:

✔ Matrix LED Layout

Hundreds of LEDs placed in a grid ensure even luminance.

✔ Ultra-Thin Body

Most LED sheets fit within 2–4 cm lighting cavities.

✔ Zero Hot Spots

The density of the LED array eliminates “dotting” and strip shadows.

✔ Easy to Cut

Modules have cutlines that allow custom sizing without electrical risk.

✔ High Brightness & CRI

Bright enough to illuminate 15–25 mm thick onyx.

✔ Stable for 24/7 Use

Ideal for hotels, retail, bars, and public spaces.

For professional backlit stone applications, LED Sheet Light is considered the industry standard.

To compare brightness, uniformity and installation depth, read: LED Sheet Light vs LED Strip — Full Comparison

What Installation Depth Is Required Behind Onyx?

Recommended installation depth is 20–80 mm depending on stone thickness and translucency. Thinner, more translucent stones require less depth; darker stones require more.

Depth guidelines:

| Stone Type | Thickness | Recommended Depth |

|---|---|---|

| High-translucency onyx | 10–15 mm | 20–30 mm |

| Standard onyx | 15–20 mm | 30–50 mm |

| Dense or dark onyx | 20–30 mm | 50–80 mm |

Tips:

Add a frosted acrylic diffuser if space is < 25 mm

Ensure cavity is fully closed to avoid light leakage

Leave ventilation space for driver cooling

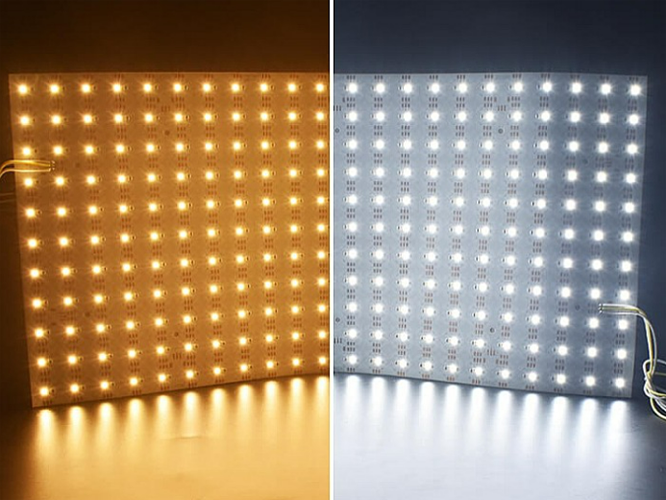

What Color Temperature Works Best for Backlit Onyx?

The best CCT range for backlit onyx is 3000K–4000K. Warm tones enhance golden veining; neutral white preserves natural color.

Recommendations:

3000K (Warm White)

Enhances yellow and honey tones

Best for hospitality environments

3500K–4000K (Neutral White)

Most natural appearance

Widely used for feature walls

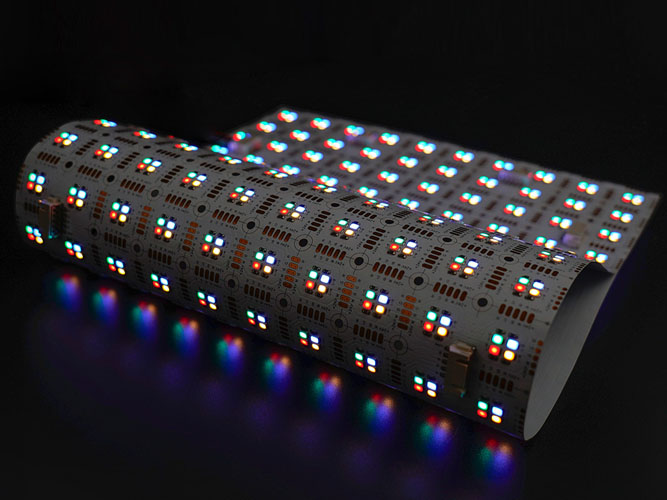

RGBW / Pixel RGBW

Ideal for bars, artistic installations, dynamic walls

Offers color-changing effects and programmable animations

LED Sheet Light vs LED Strip Light — Which Performs Better?

LED Sheet Light is significantly better for backlit onyx due to uniformity, brightness, diffusion performance, and smaller installation depth.

| Category | LED Sheet Light | LED Strip Light |

|---|---|---|

| Uniformity | ⭐⭐⭐⭐⭐ | ⭐⭐ |

| Hot Spots | None | Visible |

| Installation Depth | 20–40 mm | 70–100 mm |

| Coverage | Full-surface | Line output |

| Brightness | High | Medium |

| Cutting Flexibility | Very flexible | Limited |

| Best Use | Backlit stone & panels | Linear lighting |

If you also work with marble or quartzite, check: Backlit Marble & Stone Feature Walls — Complete Guide

How to Ensure Uniform Backlighting Behind Onyx?

Use consistent spacing, frosted diffuser, correct brightness, proper alignment, and sufficient installation depth.

Key engineering points:

1. Use frosted acrylic to soften hotspots

Especially when cavity < 30 mm.

2. Ensure flat and stable mounting

Any angle change affects diffusion.

3. Avoid “lighting gaps”

Sheets must overlap or be placed edge-to-edge.

4. Choose sufficient brightness

784-chip sheets provide more punch for thick stone.

5. Test with the actual stone slab

Every onyx slab behaves differently.

How to Choose the Right LED Sheet Model?

392 is for standard brightness, 784 for Tunable White 2700K-6500K adjustable, and RGBW for color-changing or decorative applications.

Where Is Backlit Onyx Commonly Used?

Backlit onyx is widely used in hotels, bars, luxury homes, restaurants, and retail environments.

Popular applications:

Hotel lobby feature walls

Luxury bar counters

Reception desks

SPA and wellness centers

Residential feature walls

Restaurant partitions

Retail brand displays

Installation Tips for Designers & Contractors

Test illumination with real stone, ensure ventilation and diffusion, choose correct brightness, and plan wiring layout carefully.

✔ Pre-Test Lighting with the Stone

Every slab reacts differently to light.

✔ Add Diffuser Panel if Needed

Frosted acrylic (2–3 mm) improves uniformity.

✔ Leave Space for Heat Dissipation

Even efficient LEDs need minimal airflow.

✔ Use Proper Wire Gauge

Long runs require voltage compensation.

✔ Plan Power Supply Placement

Keep driver accessible for future maintenance.

For installation and depth planning, follow this full tutorial: How to Backlight Translucent Stone

Conclusion

Backlit onyx delivers a stunning, luxurious visual effect when paired with the right lighting system. LED Sheet Light ensures perfect uniformity and consistent brightness, making it the most reliable solution for premium stone backlighting projects.

Looking for LED sheet lighting for your backlit onyx project?

AiDiWatt Lighting provides 392, 784, and RGBW LED sheets with factory-direct support.

Contact us for a fast quote and technical guidance.