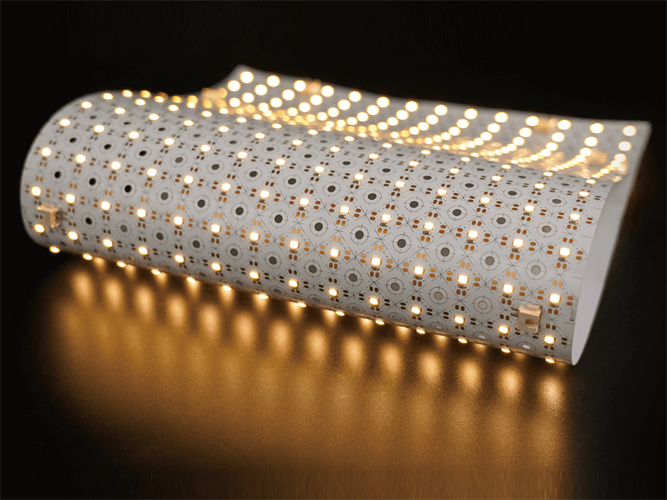

The overall design and structure of LED strip lights are very intricate; even the smallest factors can influence the price of these luminous wonders. The significance of understanding these determinants cannot be overstated, especially for LED suppliers, investors, and business owners seeking to make informed decisions in this complex industry.

To understand the pricing dynamics, we will go through the key factors that shape the cost of LED strip lights. From LED encapsulation to chip selection, and from color consistency to brightness levels, every aspect plays a vital role. Let us now decipher the pricing code behind these fixtures.

10 Key Factors that Determine the Price of LED Strip Lights

1. The Encapsulation of the LED: Resin vs. Silicone Dilemma

The encapsulation of LED strip lights involves a fundamental choice between resin and silicone. Resin encapsulation, with its cost-effective profile, is the preferred choice for many applications.

However, when heat dissipation is of paramount importance, silicone encapsulation takes the lead. While both options offer protection and sealing, the enhanced heat dissipation capacity of silicone can justify a slightly higher price.

Always consider factors like the operating environment, heat generation, and the longevity of your LED strip lights when choosing between resin and silicone encapsulation.

2. The Selection of LED Chips: Domestic vs. Imported

The selection of LED chips spans a global spectrum, offering an extremely vast array of selections. Domestic chips from China and Taiwan stand alongside their imported counterparts, which include American, Japanese, and German chips.

The price of LED strip lights can vary significantly based on the origin of the chip used. American chips, known for their cutting-edge technology and performance, come at a premium. Japanese and German chips also offer high-quality performance but at a slightly lower price point.

Meanwhile, Chinese and Taiwanese chips, while more budget-friendly, may exhibit minor variations in heat dissipation.

3. LED Strip Light Color: A Palette of Pricing

The palette of LED colors encompasses a diverse range as well. For instance, white and green LEDs are more challenging to produce consistently due to the complexities of color matching and spectral separation. As a result, they often command higher prices.

On the other hand, common LED strip light colors such as red, yellow, and blue LEDs are easier to separate and maintain color consistency, making them more budget-friendly options. Special colors like purple and brown, being less common and requiring unique production processes, tend to be the most expensive.

4. LED Strip Light Brightness: The Illuminating Factor

LED brightness is a key determinant in the pricing of LED strip lights. Brightness levels can vary significantly from one LED strip to another, and this directly impacts both cost and performance. It’s essential to determine your specific brightness requirements based on the intended application.

High-brightness LEDs tend to be more expensive, but they are ideal for applications where strong, uniform illumination is crucial, such as task lighting in commercial settings. However, for ambient or decorative lighting where a lower brightness level suffices, opting for standard brightness LEDs can lead to cost savings without compromising the desired lighting effect.

5. LED Fixture Size: Small but Significantly Different

The size of LEDs plays a more critical role in pricing and performance than is often acknowledged. Different sizes, such as the compact 0603 and the more substantial 3528, come with distinct attributes. Smaller LED strip lights are often more cost-effective, but they may produce less light and generate lower heat.

Larger LED strip lights, while pricier, offer enhanced brightness and heat dissipation. When selecting LED strip lights, consider the trade-offs between size, cost, and performance. It’s advisable to align the LED size with the specific lighting requirements of your target project, striking a balance that ascertains optimal illumination.

6. LED Chip Size: Sizing up the Price Difference

LED chip size is another primary factor in LED strip light pricing. Smaller chips, like the 0603, are more compact and less expensive, but they produce lower light output. Larger chips, such as the 5050, are pricier but provide enhanced brightness.

Understanding the price variances associated with different chip sizes enables you to make precise decisions. Smaller chips are suitable for applications where space constraints are essential, while larger chips offer superior illumination for larger areas.

7. LED Strip Light Color Consistency: Balancing the Spectrum

Small packaging factories sometimes face challenges in maintaining consistent color output due to the absence of spectrophotometers. Color consistency is pivotal for achieving uniform lighting effects. Inconsistencies in color can result in uneven illumination and a less appealing aesthetic.

To guarantee color consistency, manufacturers utilize spectrophotometers to precisely control and calibrate the color output of each LED in the strip. Investing in LED strip lights with this level of color consistency can impact pricing but ensure a superior lighting experience.

8. LED Welding: Manual vs. Machine

The method of LED assembly profoundly influences the quality and price of LED strip lights. Manual welding, performed using soldering irons, is the more traditional approach. However, this method often results in less polished appearances and can lead to challenges in maintaining electrostatic protection.

In some cases, manual welding can result in aesthetic imperfections, such as inconsistent solder joint size and flux residues. Machine welding, achieved through reflow soldering, offers a more advanced and refined assembly process. It results in LED strip lights with uniform and aesthetically pleasing solder joints, no flux residue, and intact LED packages.

Furthermore, machine-welded LED strip lights exhibit improved electrostatic protection, reducing the risk of chip burnout. While machine-welded LED strip lights may command a slightly higher price, the enhanced quality and performance they deliver often justify the investment

9. FPC (Flexible Printed Circuit) Material Used

FPCs are available in two primary varieties: copper-laminated and calendered copper. Copper-laminated FPCs are more cost-effective but may exhibit some shortcomings, such as the potential for pad peeling when bent.

Calendered copper FPCs, on the other hand, are slightly more expensive but offer greater durability and resilience when subjected to bending or flexing. The choice between these materials hinges on the specific requirements of your LED strip light application.

Copper-laminated FPCs are suitable for situations where cost is a priority, but you should exercise caution when dealing with applications that involve frequent bending or flexing. Calendered copper FPCs are a preferred choice when robust and reliable flexibility is a necessity.

10. Environmental and UL Certification: An Assurance of Quality

Certifications and quality assurances are also integral aspects that influence LED strip light pricing. LED products that have obtained certifications, such as UL (Underwriters Laboratories), and meet environmental standards often command a premium price. These certifications indicate that the products have undergone rigorous testing to ensure safety, performance, and compliance with industry standards.

While certified LED strip lights may carry a higher price tag, they offer peace of mind in terms of quality, safety, and reliability. For investors, suppliers, and business owners, the decision to invest in certified LED strip lights can lead to greater customer trust and satisfaction, ultimately benefiting your reputation and long-term success in the industry.

Frequently Asked Questions

VIDEO - 6 Important Things You Must Know to Choose the Right LED Strip

How Much Does It Cost To Have LED Strip Lights?

Installing LED strips separately offers a more flexible approach but may incur diverse costs. The price spectrum for standalone LED strips is influenced by factors such as color, length, and other specifications.

Typically, individual LED strips can range from approximately $20 to upwards of $50 each. The variation in cost can be attributed to the specific attributes of the LED strips, encompassing their quality, brand, and distinctive features.

How Do You Determine The Quality Of LED Strip Lights?

The quality of LED strip lights is determined by evaluating several key factors.

First, the thickness of the copper used in the PCB board influences efficiency, as thicker copper allows for better current flow. Secondly, the purity of the copper affects resistance and current strength, with purer copper offering superior performance.

Third, the quality of the phosphor in the LED chip impacts efficiency and brightness. Finally, consistent component selection is essential for a professional appearance and efficient performance.

Are LED Strip Lights Cheap to Operate?

Indeed, LED strip lights are exceptionally economical to operate, primarily owing to their exceptional energy efficiency. Unlike traditional lighting sources, LEDs convert a remarkable 90% of their energy into light, which makes them one of the most cost-effective illumination options available.

For instance, the annual cost of running a standard 10W LED strip light amounts to roughly $13. In stark contrast, if you were to opt for an equivalent incandescent light source, your energy expenses would soar to approximately $80 per year.

Conclusion

For those LED suppliers, investors, business owners, and enthusiasts who want to know the factors that influence and determine the cost of LED strip lights, we hope that this article has helped you find such answers.

The above-mentioned 10 key factors provide a compass for navigating the LED strip light market. Thus, it becomes evident that understanding LED strip light pricing is not merely a matter of cost but also a matter of customization and optimization. Making informed decisions in this intricate industry requires a deep comprehension of these factors.