With careful attention to technical details, it is essential to know the intricate construction intricacies, unveiling COB LED strip’s captivating luminosity and regular LED strip’s optimal efficiency.

In summary, the key difference lies in their construction. LED strip, with its Chip-on-Board technology, offers a smooth and continuous light output due to the closely packed LED chips on a single surface. In stark contrast, a customary LED strip is composed by integrating discrete LEDs onto a circuit board.

Hopefully, by the end of this captivating exploration, you will possess the knowledge to make an enlightened choice and harness the radiance that these LED strip light options offer.

What is a COB LED Strip?

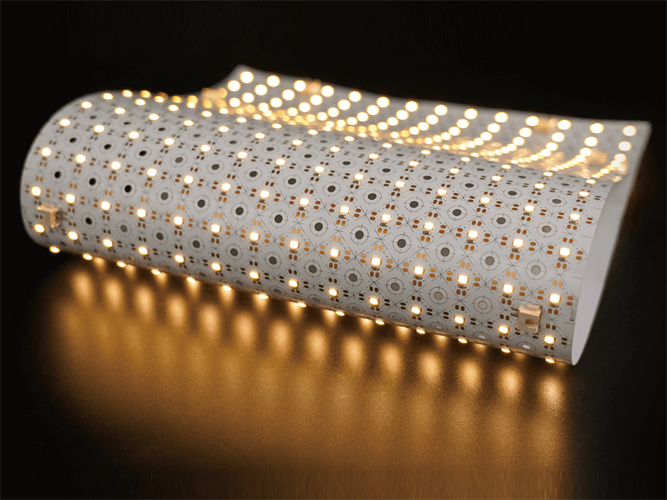

In the world of state-of-the-art illumination technology, one routinely encounters the mesmerizing Chip-on-Board strip, commonly dubbed the COB LED strip. Diverging from their conventional brethren, COB LED strips proudly flaunt an awe-inspiring manufacturing technique, rendering them truly exceptional.

Each individual diode is meticulously printed directly onto the circuit board, eliminating any spatial gaps between them. This dense arrangement is then enrobed in a phosphor gel, unveiling a mesmerizing continuous illumination effect.

The resplendence of COB LED strips transcends the bounds of their captivating luminosity. Some variants of COB lighting strips even offer the remarkable feature of tunable CCT (correlated color temperature) and RGB color technology.

With a mere caress of a remote control or by means of an intuitive application, users can effortlessly manipulate the color temperature at will or select from an exuberant array of RGB colors, thereby facilitating a multifaceted and animated illumination journey.

What is a Regular LED Strip?

Generally speaking, regular LED strip lights herald a revolutionary and multifaceted luminary alternative. Ordinarily, these strips comprise a multitude of meticulously affixed individual LED strips, ingeniously embedded onto a slender and pliable circuit board.

Operating on low-voltage DC power, they offer both energy efficiency and safety. These remarkable strips come in an extensive array of fixed and variable colors, as well as brightness levels, catering to diverse lighting preferences.

Packaged in lengthy reels, often around 16 feet, they can be conveniently cut to desired lengths. Equipped with double-sided adhesive, they ensure effortless and secure mounting, providing a flawless lighting experience.

Assessing the Inner Workings

COB LED strips and regular LED strips differ significantly in their inner workings, resulting in distinct characteristics and performance.

The Inner Workings of COB LED Strips

The COB LED strip, customarily referred to as the Chip on Board LED strip, distinguishes itself through its unparalleled manufacturing methodology. In this design, individual LEDs are directly printed onto the circuit board, eliminating any spatial gaps between them. The phosphor film greatly covers the panel, the chip is located on the side, and the solder points are placed underneath.

These diodes are meticulously arranged in immediate proximity and ensconced within a phosphor gel medium, thus engendering a seamless and uninterrupted luminous phenomenon. The absence of gaps ensures a smooth and uniform light output, offering enhanced brightness and reducing the risk of visible “hot spots” or uneven lighting.

The Inner Workings of Regular LED Strips

Within a customary LED strip, discrete LED emitters are intricately positioned upon a circuit board. These LEDs are spaced apart along the strip, resulting in discrete points of light. It is composed of the LED chip in the middle, phosphor encapsulation, L-frame solder points, and plastic reflector.

The spacing between LEDs can vary, influencing the overall light distribution and intensity. While a regular LED strip can provide adequate illumination, it may exhibit some inconsistencies in terms of brightness and uniformity due to the gaps between the individual LEDs.

Similarities

Nevertheless, both COB LED strips and conventional LED strips are purposefully engineered to avert the accumulation of excessive thermal energy. The circuit board integrated into these strips diligently assumes the role of a heat sink, adroitly diverting heat away from the individual LED components and proficiently dissipating it.

This intrinsic attribute guarantees the safety of deploying both variants of LED strips even within environments sensitive to temperature fluctuations. In certain instances, particularly with high-power LED strip luminaires, it may be judiciously advised to affix supplementary heatsinks, such as aluminum channels, to optimize the conduction of heat and augment the overall efficacy of the lighting fixture.

Comparing the Luminosity Performance

In the battle of luminosity prowess, COB LED strips and conventional LED strips reveal discernible differentials.

COB LED Strips - Brightness Capabilities

COB LED strips confer an unequivocal advantage in terms of luminosity performance. It features a smooth and continuous lighting source without the prominent individual LED dots that are visible in regular SMD (Surface Mount Device) strips.

This absence of visible dots creates a more uniform brightness. COB LED strips produce a soft, steady light that spans from end to end. The absence of prominent hotspots contributes to a more pleasing visual experience, especially when the light source is directly visible.

In contrast to conventional LED strips, which may manifest discernible individual LED dots upon direct observation, COB LED strips bestow a seamlessly uniform luminous source. This makes them an excellent choice for installations where the strip will be exposed and visible, ensuring a seamless and attractive glow.

COB LED strips are also particularly well-suited for creating stunning lighting effects on shiny surfaces such as glass or granite.

COB LED strips are ideal for applications where the illuminated surface is in close proximity to the light bar. Due to their superior brightness performance, COB LED strips can effectively illuminate surfaces that are within 2 feet, providing ample light output to ensure visibility and visual impact.

COB LED strips possess the inherent capability to engender a mesmerizing neon-esque ambiance. With their high brightness output and continuous illumination, they can mimic the vibrant and dynamic appearance of traditional neon lights.

Regular LED Strips - Brightness Capabilities

The magnitude of luminosity exhibited by a standard LED strip is conventionally quantified through the unit of lumens, which serves to measure the volume of discernible light emitted. Unlike the determinative wattage rating employed for traditional incandescent bulbs, the assessment of brightness levels in LED strips transcends the singular parameter of wattage due to variances in operational efficiency.

Rather, luminosity is frequently evaluated in lumens per foot or meter, representing a metric that captures the density of radiance. A superior-grade LED strip typically furnishes no less than 450 lumens per foot, thereby matching the luminous output of a conventional T8-type fluorescent lamp.

The brightness performance of a regular LED strip is contingent upon a multitude of influential factors. Foremost, the luminous yield and efficacy of each individual LED emitter assume a prominent role. Moreover, the quantity of LEDs per linear foot and the corresponding power consumption per linear foot contribute synergistically to the overall brilliance exhibited.

It’s important to note that LED strips without a specified brightness in lumens should be approached with caution. Similarly, low-cost LED strips that claim exceptionally high brightness may risk overdriving the LEDs, leading to premature failure.

Analyzing the Evenness of Light Distribution

COB LED Strips - Distribution of Light

COB LED strips, renowned for their illumination proficiency, possess a remarkable advantage in terms of light propagation. Through the ingenious application of Chip-on-Board technology, COB LED strips feature an intricate amalgamation where closely positioned LED chips are artfully imprinted onto the very surface of the circuit board.

This ingenious arrangement yields a fluid and uninterrupted luminous panorama, effectively eradicating any perceptible voids that could potentially manifest between the individual LED modules. The result is a remarkably even distribution of light, creating a smooth and consistent glow across the entire length of the strip.

The uniformity of luminous dispersion furnished by COB LED strips renders them exquisitely tailored for scenarios demanding superabundant illumination. Whether employed for accentuating architectural marvels, orchestrating artistic installations, or adorning spaces with ornamental brilliance, COB LED strips unfailingly deliver a harmonious and aesthetically gratifying radiance.

Regular LED Strips - Distribution of Light

Conversely, traditional LED strips, characterized by the arrangement of discrete LED strips affixed onto a pliable circuit board, frequently manifest disparities in the dispersion of light. The spacing between the LEDs can result in uneven illumination, causing visible gaps where the light intensity may be higher.

While advancements in design and manufacturing have reduced this issue, some degree of inconsistency may still be present, especially when the strip is viewed directly or when the illuminated surface is at a close distance.

Examining the Applications and Flexibility

The Applications and Flexibility of COB LED Strips

COB LED strips showcase a plethora of versatile applications. One paramount virtue intrinsic to COB LED strips lies in their capacity to engender an impeccably equilibrated illumination outcome. This makes them ideal for installations where a smooth and consistent glow is desired, such as cove lighting, accentuating architectural details, or creating indirect lighting effects.

When it comes to pliability, COB LED strips exhibit exemplary flexural properties attributable to the compact arrangement of their diodes. This attribute endows them with effortless malleability, facilitating seamless curvatures and seamless navigation around corners or constricted areas.

Indeed, the innate flexibility of COB LED strips empowers imaginative and meticulous installations, rendering them an apt choice for ventures that demand intricate or unconventional lighting configurations.

The Applications and Flexibility of Regular LED Strips

In general, regular=type LED strips proffer flexibility in both conceptualization and implementation. These strips present an extensive assortment of dimensions, LED densities, and color variations, thus presenting an expansive gamut of alternatives to harmonize with diverse lighting requisites.

In addition, regular LED strips are commonly used for task lighting, under-cabinet lighting, or creating decorative lighting effects. Their versatility allows them to be easily adapted to fit various spaces and shapes, providing functional and customized lighting solutions.

Regular LED strips offer greater flexibility in terms of installation and customization. Frequently accompanied by an adhesive backing, these strips effortlessly facilitate their mounting in an assortment of disparate settings.

Additionally, regular LED strips can be cut at specified intervals, allowing users to adjust the length to fit their specific requirements. This remarkable versatility empowers users to fashion bespoke lighting compositions, integrating them into their designated environments with effortless precision.

Conclusion

COB LED strips as well as regular LED strips clearly vary in terms of their general construction, brightness capabilities, distribution of illumination, certain applications, along with flexibility. Understanding these differences can help make informed decisions when choosing the appropriate LED strip for specific lighting needs.

COB LED strips excel in seamless and uniform illumination, crucial for applications requiring even light distribution. Regular LED strips offer versatile customization, ideal for diverse lighting needs. By maximizing their unique qualities, one can elevate designs and create captivating visual experiences.