This is an article on how to identify the quality of COB LED Strip Light, after reading it, you will know why the price difference is so big on the market, and know how to choose the suitable COB LED Strip Light.

What is COB LED Strip Light?

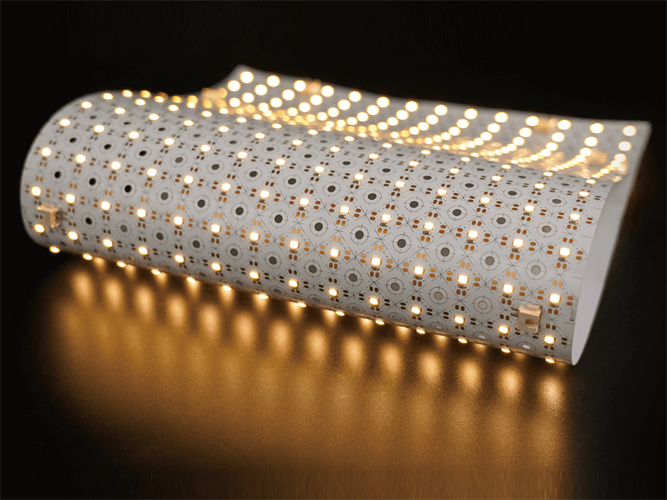

The full name of COB is the Chip On Board: directly package the chip on the circuit board. “Chip on Board” LEDs for flexible cob led strip lights are sometimes referred to as flip-chips. Flip chip LEDs are basically a bare-bones approach to LED construction.

Take a look at an ordinary SMD (Surface Mount Device) LED. It has a Lamp bead holder that package the LED chip and then covers it with a phosphor coating. The ‘flip chip’ that makes up the COB LED strip removes everything from its design, except for the LED chip, yellow phosphor cover layer, and connection pads.

The COB led strip is a high-density led lighting strip made by COB encapsulation, which can reduce the thermal resistance of the high-density strip circuit system, greatly improves the life of the LED, and the light flux density is high, the glare is small, and the light is uniform and there is no dark area.

Importance Of Selecting High-Quality COB LED Strip Lights

As an importer of LED strip lights, you know how crucial it is to source products that meet the highest quality standards. You don’t want to end up with a batch of subpar COB LED Strip Lights that fail to impress your customers or worse, lead to safety issues.

Imagine you’re showcasing your latest shipment of COB LED strip lights to a potential client. You plug them in, and they glow with a beautiful, bright light. Your client is impressed and ready to place an order. But as you pack up to leave, you notice that there are some parts stop working, LED chips dead.

You realize that these COB LED Strip Lights are not up to par, and if you sell them to your client, you risk damaging your reputation and losing their business. This is why it’s essential to know how to judge the quality of COB LED strip lights before importing them.

In this article, we’ll discuss some key factors to consider when evaluating the quality of COB LED strip lights, so you can make sure that you’re sourcing only the best products for your business.

Factors To Consider When Choose Suitable COB LED Strip Lights

1) FPC circuit board

FPC circuit board, also known as flexible circuit board, is mainly synthesized using printing technology, etching technology, and pressing technology. It applies a dry film onto a flexible substrate and produces conductive circuits on the substrate after exposure, development, and etching. Compared with rigid printed circuit boards, FPC circuit boards can be bent, have smaller size and lighter weight, and play a role in conducting and bridging in electronic products, improving product performance and reducing size.

For flexible LED strips, there are single-sided and double-sided FPC. We use double-sided FPC, which have a 5-layer structure: a high-temperature resistant PI film, a layer of copper foil for surface circuitry, another layer of high-temperature resistant PI film in the middle, a copper foil layer for the main electrical conductivity at the bottom to reduce voltage drop, and a high-temperature resistant PI film at the bottom.

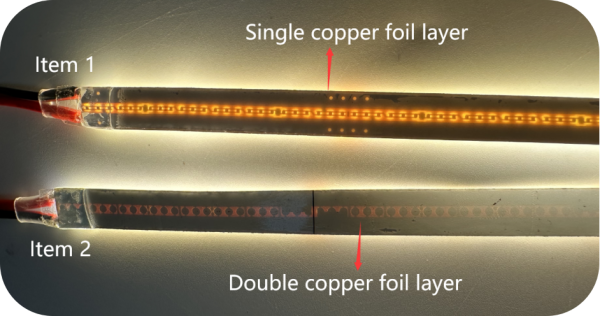

How to judge single layer PCB or double layers PCB of LED Strip Light?

1). Light up the led strip light.

2). Remove the 3M tape on the back.

3). Check the PCB board:

For single copper foil layer PCB board, you can see the electrical circuitry clearly.

For double copper foil layers PCB board, you can not see the electrical circuitry clearly, there are some shadows. Because the second copper foil layer on the back of the first copper foil layer, blocking we see the electrical circuitry.

There are two types of copper used in flexible LED strips: electrodeposited copper and rolled copper. Rolled copper is superior in all aspects compared to electrolytic copper, and we use rolled copper in our products.

| Product Name | rolled copper foil | electrodeposited copper foil |

|---|---|---|

| Price | expensive | cheap |

| Application | used for flip-phone camera modules, high-frequency and high-speed transmission, fine circuitry on a printed circuit board | Used to manufacture printed circuit boards (PCBs) |

| Colour | Yellowish | Red |

| Flexibility | 4 times more flexibility than ordinary electrolytic copper | Relatively weak resistance to bending |

| Production processes | Rolled copper is produced by coating method, which is relatively difficult to produce, but it has good ductility and can reach more than 30% | Completed through electroplating process |

| Molecular Density | Rolled copper has tightly packed molecules and good flexibility, with better flexibility in thinner sheets | Relatively loose molecules and is prone to breaking |

| Features | High strength, good resistance to bending, good ductility, electroplating and conductivity, and excellent surface gloss | Strong conductivity, low cost, prone to breaking, suitable for circuit boards with low requirements for flexibility and toughness |

There are two types of cover films available on the market: PI, PET. Another type that does not use films, printed directly with ink, like a layer of paint.

| Name | PI(Polyimide) | PET(Polyester) | Inks |

|---|---|---|---|

| Price | expensive | mid-price | cheap |

| Temperature resistance | Long-term use temperature range -200~300 ℃,One of the most thermally stable polymers to date and resistant to very low temperatures | Deformation at 150°C, melting at 267°C, low temperature resistance -100°C | Cracking and yellowing in high and low temperatures |

| Chemical stability | Flame retardant, polyimide is not soluble in commonly used organic solvents | Generally not flame retardant, poor alkali resistance, relatively stable acid resistance | Easy to corrode, flammable, and can pose a combustion risk when exposed to open flames, high heat, and oxidizers |

| Feature | High temperature resistant, good bending performance, the produced products have good reliability, and it is the main material for FPC | Generally, FPC factories rarely use it, and it is used for mesh boards or mid-to-low-end products | Prone to oxidation, poor insulation performance, and poor resistance to bending |

Electroplating process > Bowl hole process > Die cutting process

AiDiWatt Lighting’s COB LED Strip Lights use high quality double-sided FPC: a high-temperature resistant PI film, a layer of copper foil for surface circuitry, another layer of high-temperature resistant PI film in the middle, a copper foil layer for the main electrical conductivity at the bottom to reduce voltage drop, and a high-temperature resistant PI film at the bottom.

2) LED Chip

Why is it said that the chip is the most important raw material for COB LED Strip Light? Because the chip is the main component that emits light, and the quality and photoelectric performance of the COB light strip product depends on the quality of the chip. Currently, there are several relatively large chip manufacturers commonly used in the market, such as Osram, Cree, Epistar, Sanan, NationStar, Huacan, AOT, and LatticePower. The size of the chip is usually measured in length, with the larger inverted chips reaching 80x80mil and the smaller ones measuring 4x6mil and 5x5mil. Generally speaking, the larger the chip size, the higher the current it can withstand. The most used in our company is 6*20mil, 9*22mil.

Die Bonding: LED chips directly wire bonded to the PCB

COB LED strip refers to a manufacturing process where chips are directly soldered onto a flexible printed circuit (FPC) board using precise equipment and technology. A layer of glue mixed with fluorescent powder is then added to the surface of the chips to form the COB LED strip. This process eliminates the need for traditional SMD chips and holder solder process, greatly improving the product’s stability and heat dissipation, and is superior to traditional LED strips. The biggest breakthrough is the transformation from traditional point-to-point lighting to linear lighting.

3) Fluorescent Powder and Potting Glue

Fluorescent powder refers to inorganic powder that can emit light under certain excitation conditions, sometimes also called luminescent powder or fluorescent substance. Fluorescent powder largely determines important parameters of products such as color rendering index, color temperature, XY value, luminous efficiency, light decay, and so on.

Drop the mixing glue on the surface of LED chips and resistors by auto glue machine

The main function of potting glue is to protect electronic components from moisture, water, pollution, etc., by coating and sealing them. Currently, the most widely used potting glue for LED light strips in the market are organic silicon potting glue, epoxy resin potting glue, and silicone resin potting glue.

| name | silicone potting glue | expoxy resin potting glue | silicone resin potting glue |

|---|---|---|---|

| Hardness | Low hardness, 30-70A | High hardness, >55D | Medium hardness, 70A-80D |

| Weather resistance | Excellent, long lasting outdoor use without yellowing | Poor, prone to yellowing or discoloration under light or high temperature conditions. | the anti-aging ability and resistance to ultraviolet rays are weak, and the colloids are prone to discoloration. |

| Refractive index | 1.41 | 1.58 | 1.54 |

| Price | expensive | cheap | mid-price |

| Temperature resistance | -60℃~250℃ | -20℃~120℃ | -60℃~150℃ |

| Application | Suitable for applications with high stress and low sealing requirements | Suitable for applications with low stress and high sealing requirements | Between silicone and epoxy resin |

| Advantages | Excellent molding effect, resistance to thermal cycling, thermal conductivity and flame retardancy, superior flexibility, and improved stability of electronic components | Good adhesive strength to materials, good acid-alkali resistance and corrosion resistance of cured materials, excellent sealing properties, and good dielectric properties | Between silicone and epoxy resin |

| Disadvantages | Low hardness, poor resistance to external forces, inadequate sealing properties | Cured materials tend to be brittle, with poor resistance to peeling, cracking, and impact. | Between silicone and epoxy resin |

4)LED Strip Adhesive

Different types of adhesive tape should be chosen for different uses, environments, and surfaces. If the adhesive tape chosen for an LED strip is not suitable, it may not provide the best adhesion and could result in poor performance or even detachment of the LED strip after a short period of time. Therefore, it is important to carefully consider the appropriate adhesive tape for the specific application to ensure the best results.

| Photo |

|

|

|

|---|---|---|---|

| Model | Tesa 4965 | 3M 9080A | Blue Thermal Tape |

| Matereial | Acrylic foam substrate, acrylic | Non-woven substrate, acrylic adhesive | High-performance pressure-sensitive adhesive coated on both sides with a fibre mesh substrate |

| Thickness | 0.205mm | 0.17mm | 0.2mm |

| Long-term temperature resistance | 100℃ | 93℃ | 120℃ |

| Short-term temperature resistance | 200℃ | 149℃ | 180℃ |

| Features | Good resistance to ageing and shearing, solvent resistance, softening resistance, moisture resistance, excellent bonding strength and thermal conductivity, high temperature and pressure resistance. | It has good dimensional stability, thermal stability, good initial and holding adhesion, stable performance and excellent temperature resistance. | Good resistance to high and low temperatures, excellent thermal conductivity, heat dissipation and improved product life. Suitable for environments that require long-term electrical heating. |

5) Evaluating the light colour consistency of COB strips

LED light strips have high requirements for the first production yield due to the inability to effectively perform secondary BINning. This places higher demands on the production process and technology. How can we effectively assess the consistency of an LED light strip? We propose a method called “One Touch, Two Inspections, Three Measurements”.

One Touch: Hold the led strip gently in your hand, put the belly of your thumb gently on the adhesive surface and gently jerk the strip, if you can feel the adhesive surface has unevenness, then this consistency is definitely not good.

Two Inspections: The led strip will be randomly sampled, lit to see its colour consistency, after sampling these products together for comparison. If there is inconsistency in one strip, it means that the process is not stable, and if there is a significant difference between the strip and the strip, it means that it is difficult to guarantee the consistency of the batch.

Three Measurements: The COB LED strip samples just sampled were subjected to integrating sphere tests.

If you still don’t know how to identify the quality of COB strips, you can contact us and feel free to test our COB strip samples.