When architects, designers, or signage manufacturers choose Silicone Neon Flex, one of the first questions they face is: What’s the difference between Top Bend, Side Bend, and 3D Bend?

At first glance, all neon flex products look similar—flexible strips encased in durable silicone. But in reality, the bending direction determines whether your project will succeed or fail. Choosing the wrong type can mean that a logo can’t be fabricated correctly, a curved façade looks awkward, or additional installation costs arise.

This article explains the three bending types of Silicone Neon Flex, including their definitions, applications, and advantages. By the end, you’ll know exactly which type to choose for your next project.

Why Does Silicone Neon Flex Have Different Bending Types?

The secret lies in the PCB layout and extrusion process of the silicone housing.

In a Top Bend product, the PCB is oriented so that the strip can flex up and down (vertically).

In a Side Bend product, the PCB allows the strip to flex left and right (horizontally).

In a 3D Bend product, a specially designed structure enables bending in any direction, combining both vertical and horizontal flexibility.

This means not every Neon Flex can make the same shapes. Understanding bending types is essential before you start designing signage, logos, or architectural outlines.

Top Bend Silicone Neon Flex

Definition

Top Bend Series Neon Flex Strip refers to a type of flexible LED neon strip designed for bending in the vertical direction (up and down), also known as Vertical Bend. This structure allows the strip to create curves, waves, or patterns along walls or ceilings where the bending motion is perpendicular to the mounting surface.

Applications

Building outlines with vertical turns

Letters with vertical strokes such as U, n, h

Signage that requires straight lines and vertical transitions

Advantages

Widely used and cost-effective

Easy to install for vertical edges

Provides consistent light output in common lettering shapes

Example

A retail store sign with large “U” shaped letters can be easily created with Top Bend Neon Flex because it bends smoothly in the vertical direction.

Side Bend Silicone Neon Flex

Definition

Side Bend Series Neon Flex Strip, also known as Horizontal Bend Neon Flex, is designed to allow bending from left to right along its side axis. This makes it ideal for creating curves, shapes, and outlines on vertical surfaces like walls or building facades, where the strip’s body bends horizontally relative to the mounting surface.

Applications

Round shapes and curves, such as O, S, C

Smooth logo arcs

Architectural curved facades and decorative borders

Advantages

Perfect for circular and wave-shaped designs

Smooth bending radius for signage logos

Easy to adapt for creative lighting lines

Example

If a shopping mall needs a circular logo outline, Side Bend Neon Flex is the ideal choice. Its horizontal flexibility allows clean curves without visible gaps.

3D Bend Silicone Neon Flex

Definition

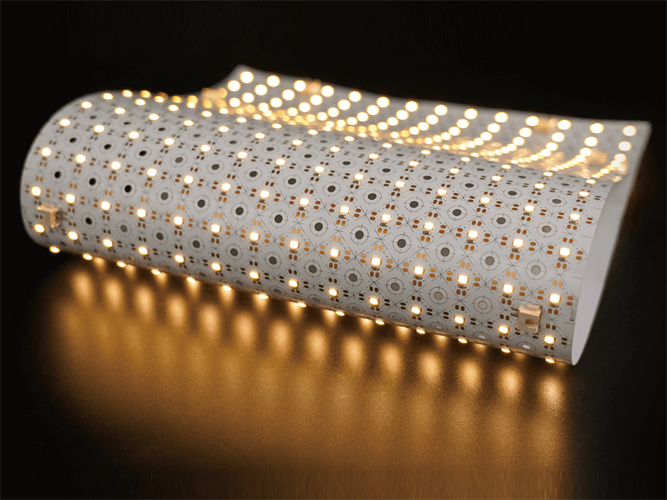

3D Bending Series LED Neon Flex is a type of flexible neon strip specially engineered to allow bending in both horizontal (side bend) and vertical (top bend) directions simultaneously. This unique flexibility enables designers to create complex, three-dimensional shapes, curves, spirals, and creative installations that traditional single-axis neon flex cannot achieve.

Applications

Complex 3D logos

Creative sculptures or art installations

Large-scale architectural lighting requiring multiple curves in different directions

Advantages

Maximum design freedom

Reduces the need for multiple product types

Enables sophisticated projects that are impossible with standard neon flex

Disadvantages

Higher cost due to complex structure

More demanding production and installation process

Example

An international hotel chain wants a 3D glowing sculpture in the lobby. Only 3D Bend Neon Flex can achieve the twisting and multi-directional shapes required.

Comparison: Top Bend vs. Side Bend vs. 3D Bend

| Type | Bending Direction | Best For | Advantages | Cost |

|---|---|---|---|---|

| Top Bend | Vertical (Up/Down) | Vertical strokes, building edges | Simple, common, cost-effective | Medium |

| Side Bend | Horizontal (Left/Right) | Curves, round shapes | Smooth arcs, flexible designs | Medium |

| 3D Bend | Any direction | Complex 3D projects, sculptures | Unlimited creativity, versatile | High |

How to Choose the Right Bending Type

For Signage and Logos

Letters with vertical strokes → Top Bend

Round or curved letters → Side Bend

For Architectural Outlines

Straight building edges → Top Bend

Curved façades or arches → Side Bend

For Creative Installations

Complex sculptures or mixed-direction logos → 3D Bend

For Budget Control

Standard projects → Top or Side Bend

High-end or custom projects → 3D Bend

Frequently Asked Questions (FAQ)

Q1: Can I use Top Bend Neon Flex for curves?

Yes, but only for vertical curves. If your design has horizontal curves (like circles), Side Bend is required.

Q2: Is 3D Bend always necessary?

Not always. 3D Bend is ideal for advanced or complex designs, but for standard signage and architectural lines, Top or Side Bend is more cost-effective.

Q3: What’s the bending radius for each type?

Top Bend: usually ≥ 60 mm

Side Bend: usually ≥ 80 mm

3D Bend: varies, but typically more flexible than both

Q4: Do these types affect brightness or color?

No. The bending type only affects the direction of flexibility, not the LED performance. Brightness and color depend on the LED chips used.

Conclusion

Choosing the correct bending type of Silicone Neon Flex is crucial for signage, architectural, and creative projects.

Top Bend is best for vertical strokes and building outlines.

Side Bend is perfect for smooth arcs and round shapes.

3D Bend offers unlimited design freedom for complex installations.

By selecting the right type, you avoid design mistakes, reduce installation costs, and ensure the final effect matches your vision.

If you’re planning signage, architectural, or creative projects and are unsure which Silicone Neon Flex to choose, contact AiDiWatt Lighting today.

We provide:

Free technical consultation

Sample kits for testing

OEM/ODM customization for your project needs

👉 Get in touch with our team to discuss your project and receive a tailored solution.

1. Top Bend Series (Vertical Bend)

Top Bend Series Neon Flex Strip refers to a type of flexible LED neon strip designed for bending in the vertical direction (up and down), also known as Vertical Bend. This structure allows the strip to create curves, waves, or patterns along walls or ceilings where the bending motion is perpendicular to the mounting surface.

2. Side Bend Series (Horizontal Bend)

Side Bend Series Neon Flex Strip, also known as Horizontal Bend Neon Flex, is designed to allow bending from left to right along its side axis. This makes it ideal for creating curves, shapes, and outlines on vertical surfaces like walls or building facades, where the strip’s body bends horizontally relative to the mounting surface.

3. 3D Bending Series

3D Bending Series LED Neon Flex is a type of flexible neon strip specially engineered to allow bending in both horizontal (side bend) and vertical (top bend) directions simultaneously. This unique flexibility enables designers to create complex, three-dimensional shapes, curves, spirals, and creative installations that traditional single-axis neon flex cannot achieve.